TexGen: An open source software for realistic geometric representation of textiles

TexGen: An open source software for realistic geometric representation of textiles

Posted on 14 April 2017

TexGen: An open source software for realistic geometric representation of textiles

By Louise Brown, Senior Research Fellow at the University of Nottingham and EPSRC Research Software Engineer Fellow

By Louise Brown, Senior Research Fellow at the University of Nottingham and EPSRC Research Software Engineer Fellow

This article is part of our series: A day in the software life, in which researchers from all disciplines discuss the tools that make their or someone else’s research possible.

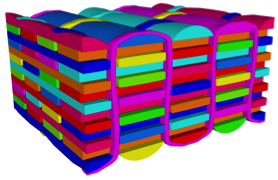

Composite materials are increasingly used in a wide range of applications, particularly in the aerospace and automotive industries. Here their low weight and high strength are a significant advantage, and they will contribute to achieve targets for reduction of greenhouse gas emissions by decreasing the weight of components and therefore energy used. They comprise a reinforcement embedded in a matrix and may be made up from many combinations of materials, typically glass or carbon fibre in a polymer matrix. Often the reinforcements are produced in the form of textiles for ease of handling, either layering ‘2D’ weaves to give the required thickness or by creating complex ‘3D’ weaves which can enhance properties and reduce manufacturing time.

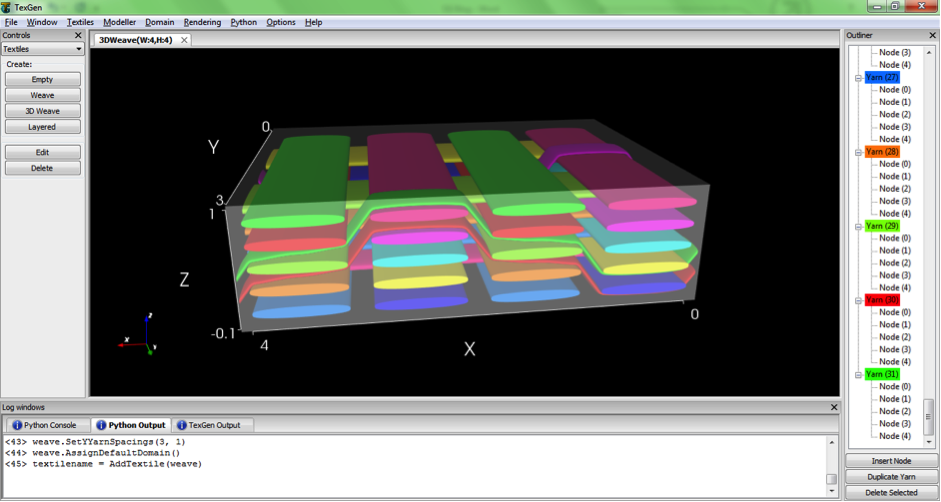

Given the many possible combinations of reinforcement textiles and matrix materials, it is beneficial to be able to model these systems so that simulations can be run to predict properties for both manufacturing processes and the final performance of the material. A “virtual testing” environment can lead to significant savings in terms of time, material and design costs. Over a number of years, the University of Nottingham has developed the TexGen software, a tool for generating a realistic geometric representation of textiles which is used as a pre-processor for simulations. The software uses a kinematic modelling approach based on the definition of yarn centrelines with cross-sections specified along the yarn length. Textiles are characterised using microscopy or µCT images and geometric features identified which are then built into TexGen. This approach has the advantage of generating models quickly without prior knowledge of the mechanical properties of the material.

Textile composites has been an active research area at Nottingham since the late 1990s when initial development of TexGen took place. Further development leading to the release of Version 3 as a cross-platform, open source software in 2006 was carried out by Martin Sherburn during his PhD studies. The software is hosted on Sourceforge under a GPL license with both source code and executables available for download. Martin left the project in 2008 and Louise Brown joined in December 2009 and has been responsible for the ongoing development of the project since then.

The decision to develop TexGen as an open-source project has provided several advantages. Making the software freely available has led to a large number of users worldwide. There were 4176 downloads of the last release over the course a year, from 68 countries. Downloads by interested parties have led to collaborations and funding of projects with both industry and academia, and the availability of the source code enables users to extend the code for their own uses. Having the code available as open source has been looked on favourably by EPSRC and was a contributing factor in being awarded Platform Grants between 2005 and 2013 and, more recently, funding for the project continues with Louise Brown being awarded an EPSRC Research Software Engineer fellowship centred round the continued development of TexGen.

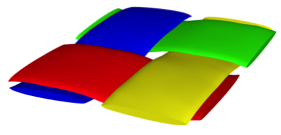

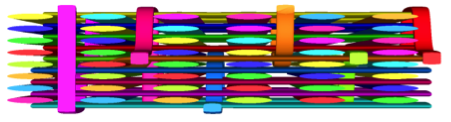

2D plain weave

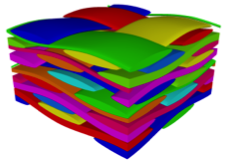

2D plain weave Layered textile

Layered textile 3D orthogonal weave

3D orthogonal weave

A modular approach has been taken, using third-party libraries for functions such as rendering and file export (VTK and OpenCASCADE), enabling research development to be concentrated on the core 3D modelling function. In particular, the use of the Simplified Wrapper and Interface Generator (SWIG) library to wrap the C++ functions in the Core and Renderer modules gives great flexibility to the system by enabling the TexGen functions to be called from Python scripts. The Python interface allows integration with other packages which have a Python capability, e.g. the Abaqus Finite Element Analysis package, and also allows specific functionality to be developed separately from the main development tree (e.g. where commercial confidentiality is required). Ongoing projects such as Breakthrough Aerospace Materials, BAM, are looking at increasingly complex weave patterns and TexGen functionality is being developed to be able to provide the utilities to model these textiles.

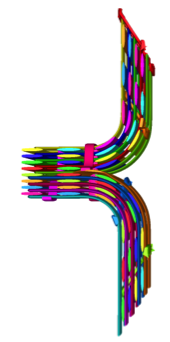

Model with bifurcation

Model with bifurcation

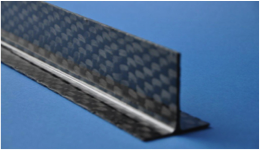

Composite T section

Composite T section

Model of 'as-woven' textile

Model of 'as-woven' textile

The software has been developed within the Composites Research Group at Nottingham and therefore its main use there has been in applications for composite materials. There are however many applications of textiles in diverse industries and future work will explore other areas of textile technology which can utilise the models created by TexGen.